The Wassara technology uses water to power the down-the-hole (DTH) percussion hammer. This makes it the superior choice for many drilling applications where air-powered DTH hammer, top hammer or rotary drilling equipment are normally used.

The water-powered technique gives no pollution as no oil is used to lubricate the hammer, only pure water is used. You get no injection of air or oil in the formation, no influence of oil in the ground water and no oil mist or dust distribution in the air – all important benefits, not least for the work environment.

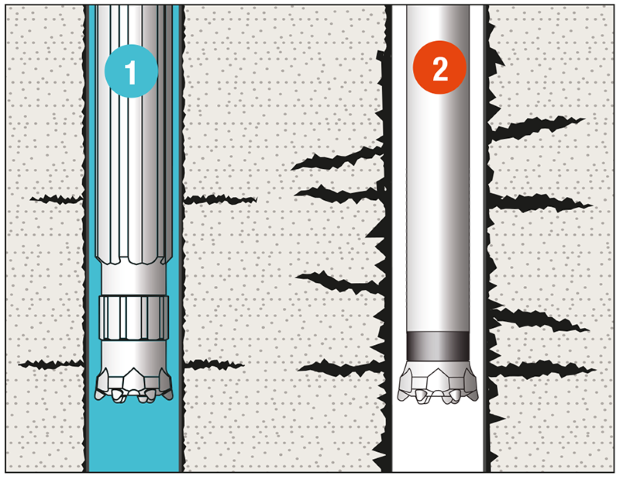

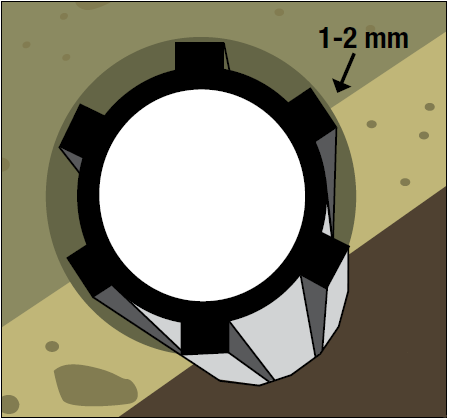

With Wassara you get straight and stable boreholes, thanks to the tight clearance between drill string and borehole. The stability is maintained by the water column's hydrostatic pressure. Also, the low up-hole velocity of the water prevents creation of cavities, which means cleaner and smoother holes. The low velocity of the return water minimizes the wear on the hammer guide ribs, making it possible to keep a tight clearance between hammer and borehole.

Since the Wassara technique itself uses water, it drills through water-rich formations without problems. The high penetration rate also provides very efficient and fast drilling through almost any material, from boulders and wood to dense clay and old foundations.

The energy consumption with Wassara is normally 50–80% less than with air-powered drilling systems. Another cost saving factor is the minimum wear on the equipment, due to the low up-hole velocity of the water.

The Wassara drilling technique minimises the risk of pressurising the formation, which ensures a minimum of disturbance to the surrounding services and adjacent structures. The ground water table is not impacted – and neither does the ground water table impact the drilling work.