Dams

When complete, the Angostura Hydroelectric Plant will deliver power to around 300 000 households. The bedrock needed water-proofing, this was ...

Angostura, Chile

Pilotes Terratest

W50 & W80 Hammer

When complete, the Angostura Hydroelectric Plant will deliver power to around 300 000 households.

The bedrock needed water-proofing, this was done by drilling 64 mm holes and then grouting with cement. The Wassara system was also used for drainage drilling with 102 mm diameter holes.

The allowed borehole deviation was set to 2% at full length. Wassara managed to meet the requirement by far. The drilling environment was healthy, friendly and comfortable as it was dust-free and held a low noise level.

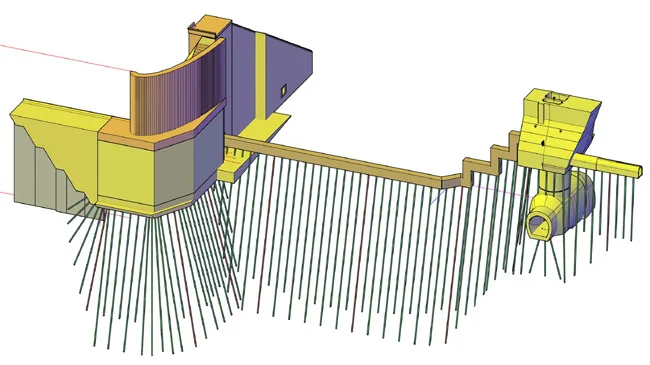

A 320 MW hydropower plant under construction

The Angostura Hydroelectric Plant is located some 600 km south of Santiago, being the largest hydropower plant being built in Chile since 2004.

A total of 200 000 m3 concrete will be used in the construction. When completed, the plant will have a generation capacity of 320 MW, enough to power around 300 000 households. The total production will be 1 542 GWh a year.

Waterproofing the bedrock

The dam is a RCC (Roller-Compacted Concrete) dam. Although the bedrock was in good condition for placing a dam on, it was stipulated that it should be made water-proof by drilling and grouting with cement. The drilling would also detect any weak or permeable zones along the dam body.

| DTH Hammer | W50 & W80 Hammer |

| Drill bits | Ø 64 mm (2.5”) & Ø 102 mm (4”) |

| Rig | Commacchio MC 235 with a 1.2 m free stroke length |

| Pump | Hammelmann HDP -127 |

| Drilling fluid | Clean water from the dam |

| Water pump | WASP 150 Diesel |

| Drill pipe | Wassara 1 000 mm, OD 48mm |

| Borehole length | 5-60 meters |

| Scope of drilling | 4 000 meters (W50) & 6 100 meters (W80) |

| Geologic formation | Sedimentary rock |

See our featured Case studies below to learn what real world Dam-projects our technology as been a part of.