Learn more about the LKAB Wassara-Hammer, its history, technology and key benefits.

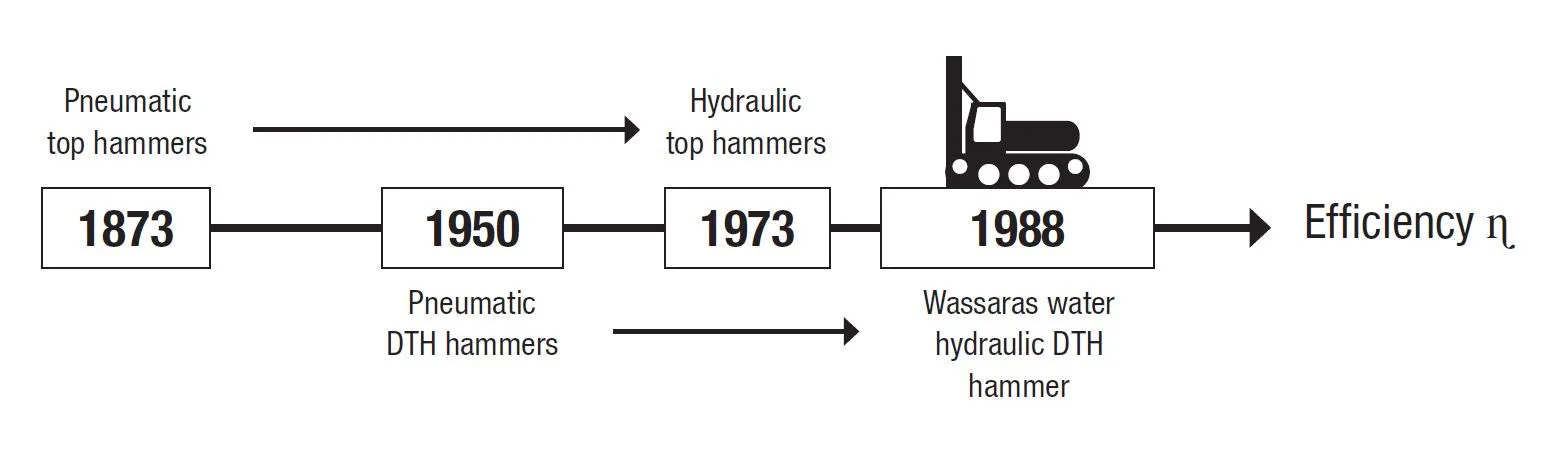

In the year 1988, engineers at LKAB Wassara developed a DTH-hammer which is powered by high pressure water instead of air.

Watch a video about our water-powered technology

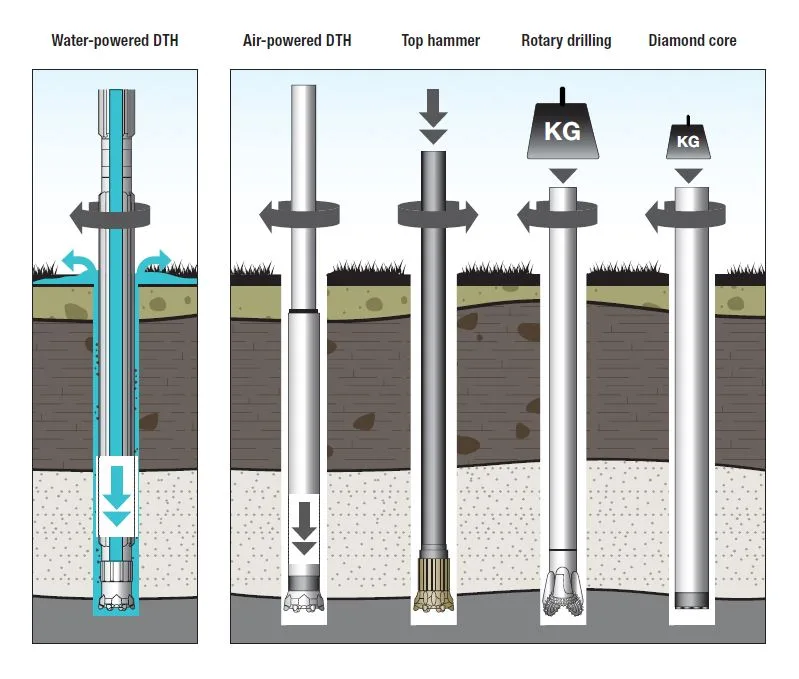

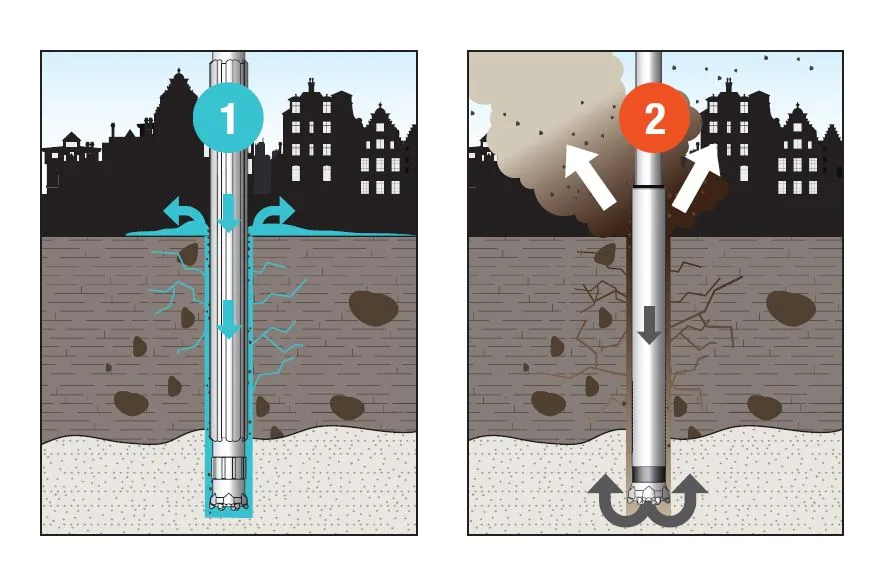

There are several benefits with using water-powered DTH compared to air-powered DTH. From a physics point of view many of the benefits arise from the fact that water is an incompressible media and air is not.

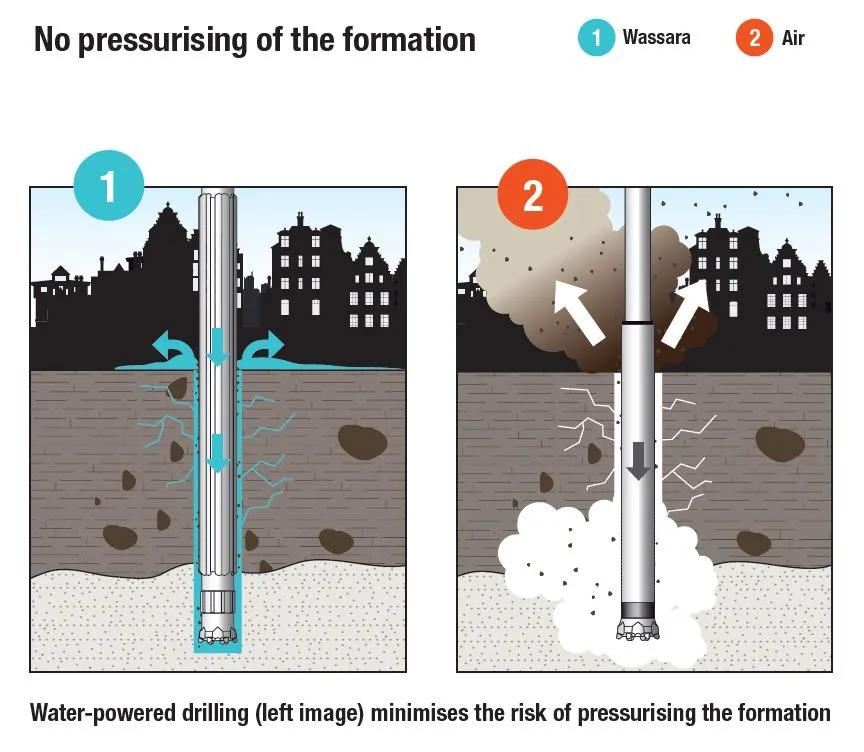

Energy consumption is roughly a quarter compared to air, resulting in lower carbon emission and a lower energy bill. In the case of water-powered DTH, the water leaving the drill bit in the hole is at a low velocity and ambient pressure.

However, with air-powered DTH the air leaving the drill bit in the hole is at a high velocity and high pressure. This means that the risk of damaging surrounding structures in sensitive areas such as urban environments and dams, is greatly reduced with water-powered DTH.

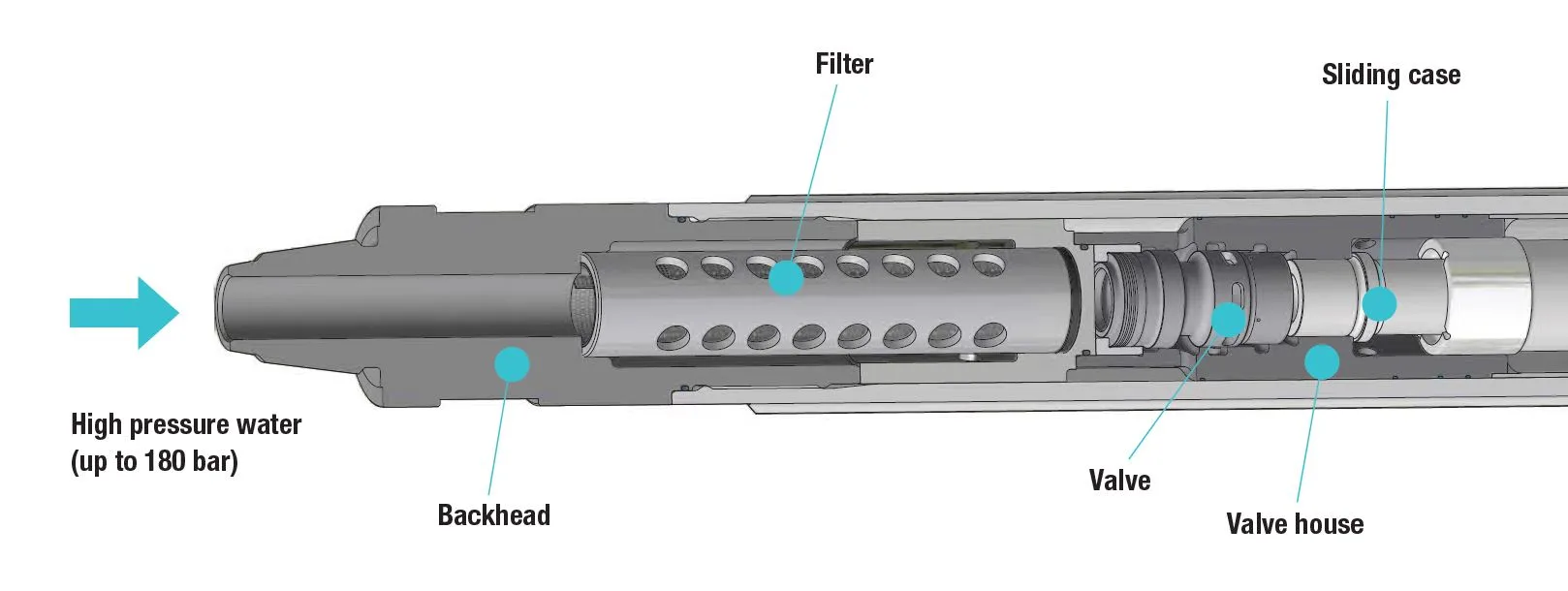

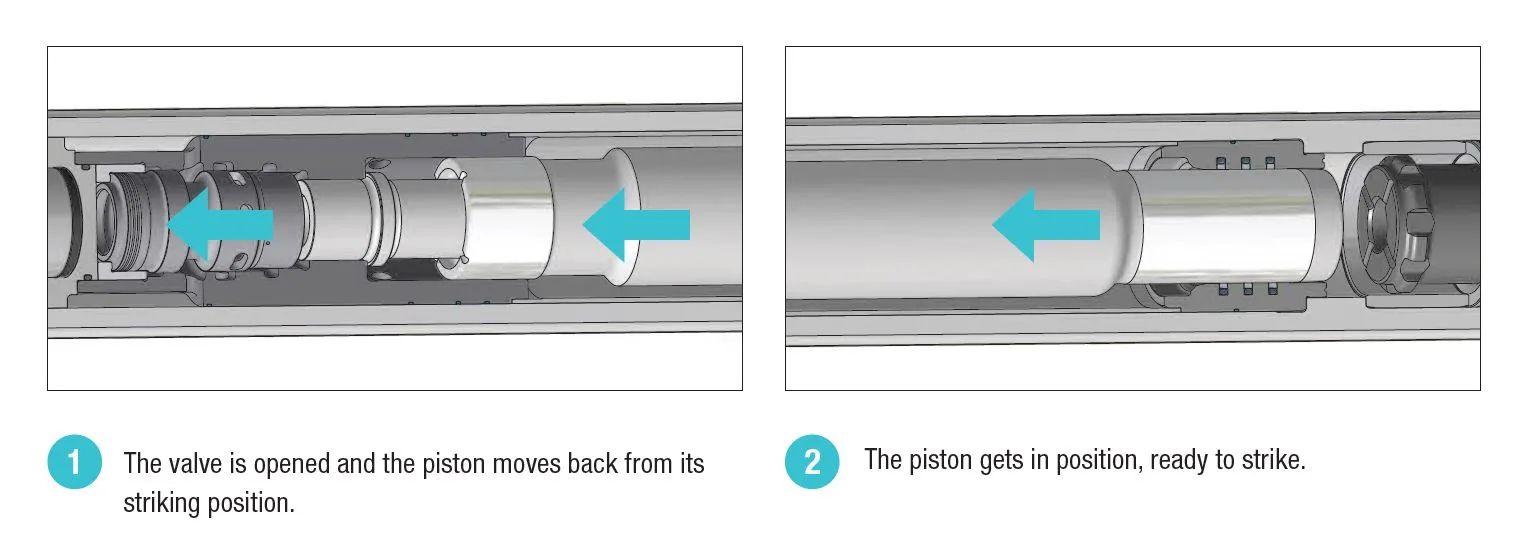

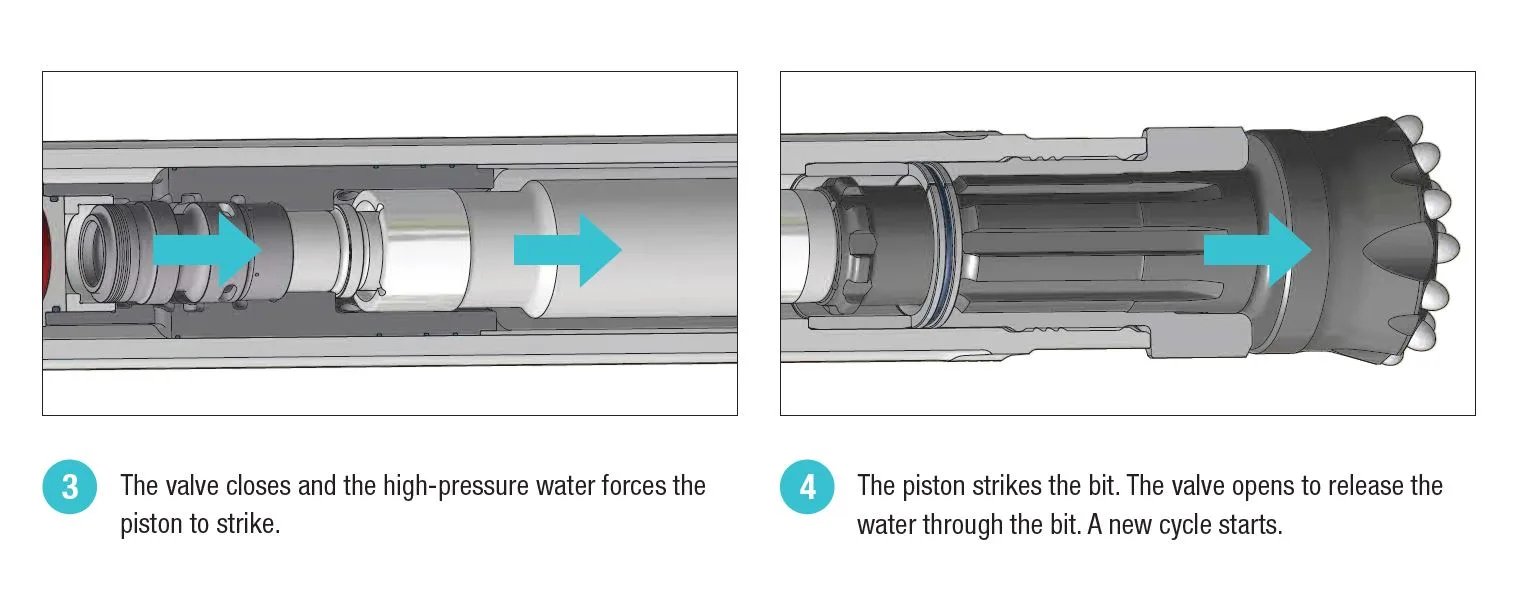

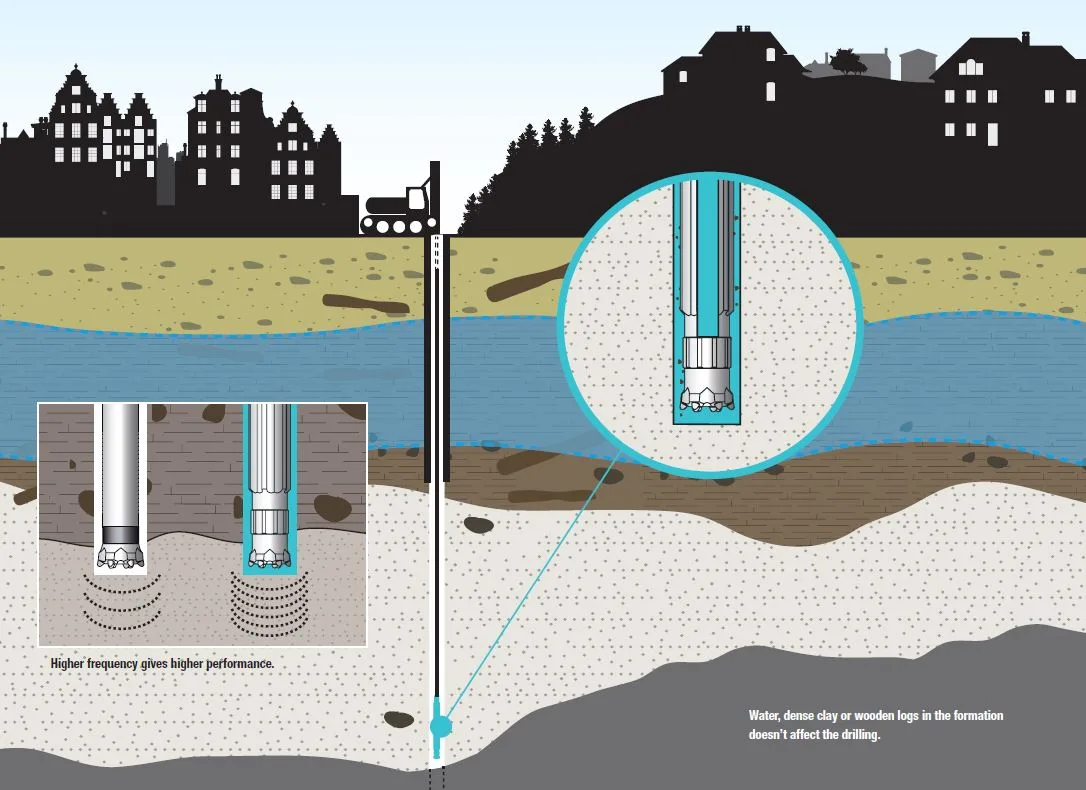

The LKAB Wassara DTH-hammer consist of only two moving parts: the piston and the valve. With so few moving parts, the smart solution delivers reliable high performance drilling in the most challenging conditions.

Water, at up to 180 bar delivery pressure, is used to power the impact mechanism of the hammer at a high frequency rate.

When the water leaves the hammer, it loses the pressure and keeps a low flush velocity. This however is still adequate to bring any cuttings to the surface and clean the borehole.

Additionally, the hydrostatic column, which is created above the hammer, helps to keep the hole stable while preventing potential collapse. This also prevents water from being drawn into the borehole, which increases hole stability and prevents potential environmental issues.

The piston in a DTH hammer always strikes directly on the drill bit. A top hammer, on the other hand, loses approximately 4-6 % of impact energy at each drill rod connection, as the percussion unit is located on the drill rig.

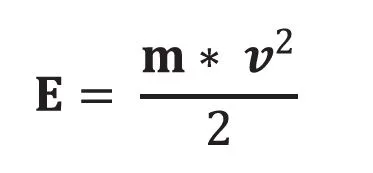

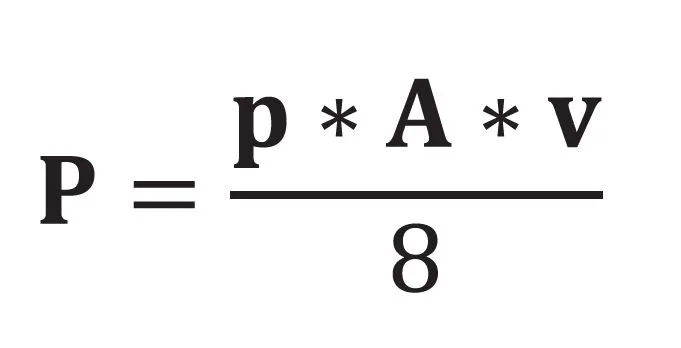

When comparing an air-powered DTH with a water-powered DTH, which, in principle, work the same way, there are significant differences. The energy per blow can be expressed as follows:

E equals the piston mass, m times the piston impact velocity, v squared and divided by 2.

The output power P equals the pressure p of the medium powering the piston, times the pistons pressurized area A, times the piston impact velocity v, all divided by 8.

The piston mass and the pressurized area are determined by the diameter of the hammer case and are therefore rather fixed. The impact velocity depends on the piston material characteristics and is therefore also a parameter which cannot be significantly improved. But the pressure of the medium powering the DTH hammer is a parameter that can be considerably increased/improved, for a hydraulic hammer.

Click on the image below to start the video and see an in-depth view of our water-powered technology.

The LKAB Wassara DTH-hammer consist of only two moving parts: the piston and the valve.

With so few moving parts, the smart solution delivers reliable high performance drilling in the most challenging conditions.

The water-powered technique gives no pollution as no oil is used to lubricate the hammer, only pure water is used. You get no injection of air or oil in the formation, no influence of oil in the ground water and no oil mist or dust distribution in the air – all important benefits, not least for the work environment.

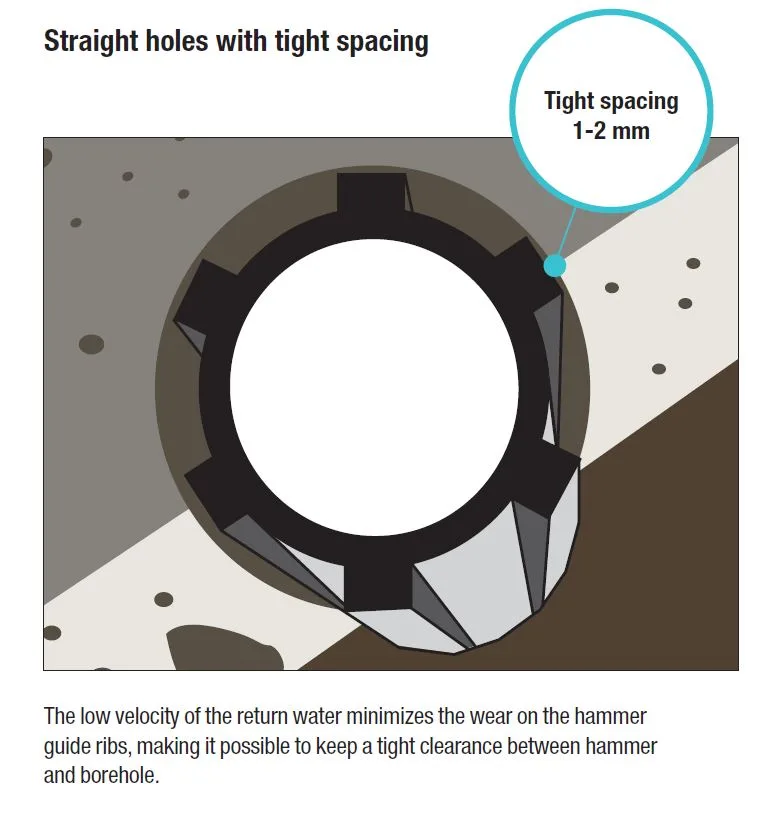

With Wassara you get straight and stable boreholes, thanks to the tight clearance between drill string and borehole.

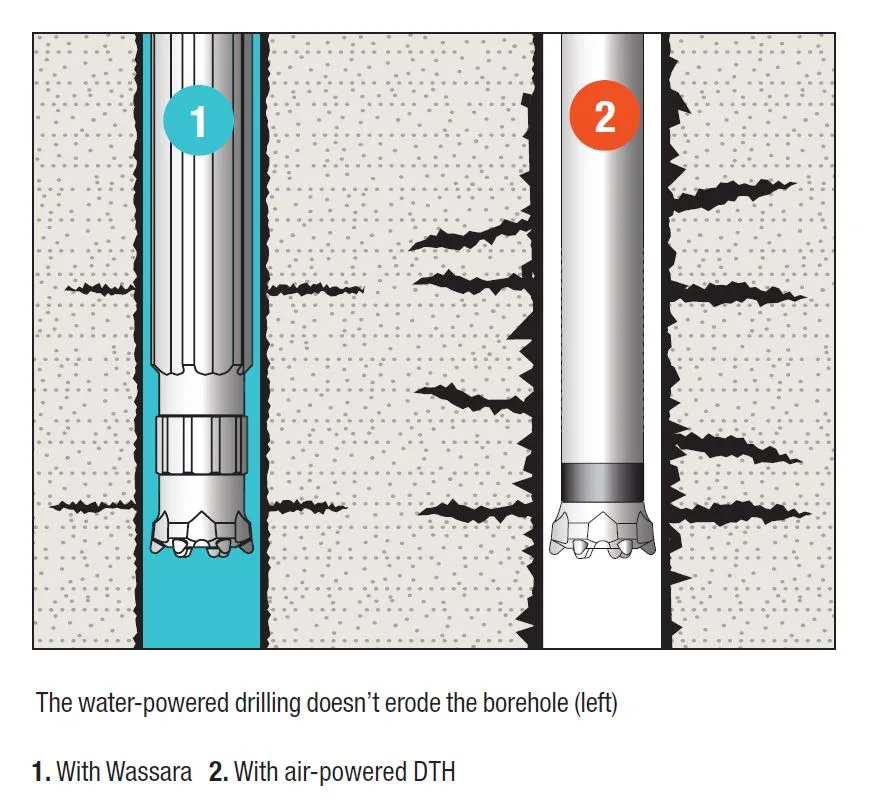

The stability is maintained by the water column’s hydrostatic pressure. Also, the low up-hole velocity of the water prevents creation of cavities, which means cleaner and smoother holes.

The low velocity of the return water minimizes the wear on the hammer guide ribs, making it possible to keep a tight clearance between hammer and borehole.

Since the Wassara technique itself uses water, it drills through water-rich formations without problems.

The high penetration rate also provides very efficient and fast drilling through almost any material, from boulders and wood to dense clay and old foundations.

The energy consumption with Wassara is normally 50–80% less than with air-powered drilling systems.

Another cost saving factor is the minimum wear on the equipment, due to the low up-hole velocity of the water.

The Wassara drilling technique minimises the risk of pressurising the formation, which ensures a minimum of disturbance to the surrounding services and adjacent structures.

The ground water table is not impacted – and neither does the ground water table impact the drilling work.

Discover the many benefits and applications of water-powered drilling